WETSUIT NEOPRENE

In 1931 DuPont invented neoprene, a type of synthetic rubber made by the polymerization of chloroprene. It is arguably the best material to use for insulation, and therefore used often to make wetsuits. It fits tight on the body, stays flexible over time and will protect you from hypothermia. The main ingredient of wetsuit neoprene is the element carbon (C), an element derived from oil. However, we now harvest this main ingredient from more environmentally friendly limestone and other sources with high carbon content. There are many types of neoprene available with different characteristics, price, applications and impact on the environment. For instance, you may have heard of different types of neoprene like CR neoprene, limestone neoprene, or Polychloroprene.

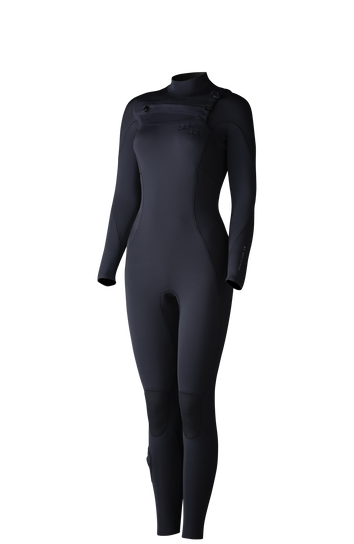

Featured wetsuits

NEOPRENE FOAM

We use neoprene foam sliced in different thicknesses to make our wetsuits. Different grades of foam have different capabilities and characteristics. Usually, the more flexible and softer the foam, the more high-end it is. In the next paragraphs, you’ll learn more about the different neoprene types available.

CR NEOPRENE: OIL OR LIMESTONE-BASED

CR NEOPRENE: OIL OR LIMESTONE-BASED

Firstly, the most common neoprene type is CR neoprene. You may know this as Chloroprene rubber, simply CR or Polychloroprene. CR neoprene can be made out of oil, which is harmful to the environment. Alternatively, we can now use a more high-end type of rubber foam that is limestone-based instead of oil-based.

PETROLEUM-BASED NEOPRENE

Petrol based neoprene is the traditional method of making neoprene as invented in the 1950s. However, this petrol based neoprene is much less environmentally friendly than the new, cleaner versions of neoprene available.

NEOPRENE AND ITS SUSTAINABLE ALTERNATIVES

NEOPRENE AND ITS SUSTAINABLE ALTERNATIVES

There are different types of neoprene used in wetsuits today. The introduction of limestone-based neoprene made a big impact on wetsuit manufacturing and is now widely used in high-end wetsuits. Some companies use different names for their limestone-based alternatives. You might have heard of Japanese Yamamoto neoprene, which is used in some high-end wetsuit models. Other versions of limestone neoprene are Bioprene and Geoprene wetsuits. Not long ago, we worked exclusively with limestone neoprene. The elongation, flexibility, and insulation characteristics of limestone neoprene can be very good compared to traditional petroleum-based neoprene, depending on the specific foam formulation. This makes limestone neoprene a popular choice for flexible and warm wetsuits.

In recent years, plant-based natural rubber foams have emerged as an alternative to traditional neoprene. Yulex was one of the first materials to bring this concept to the wetsuit market, developed in collaboration with Patagonia. Today, several natural rubber foams exist and continue to improve.

Natural rubber foams are considered among the lower-impact material options currently available for wetsuit production. They are typically double-lined, which allows for strong and durable seams between panels, helping to keep water out and retain warmth. While these materials are generally more expensive than limestone neoprene, their performance has improved significantly over the last few years and continues to evolve. In many properties, they already perform very well compared to traditional neoprene.

At SRFACE, we work with material partners to test and develop natural rubber foams. These materials are intended for use in our Eco wetsuit range and future products.

Choose your wetsuit

LIMESTONE NEOPRENE

In the 1960s it became possible to make neoprene using a different method. The main neoprene compound remains chloroprene. But instead of using dirty petroleum-based ingredients it became possible to use calcium carbonate from limestone. Limestone is often mined in Japan, where manufacturers transform it into rubber chips. After that, they melt these chips down in an oven and it goes through a chemical process. Next, they infuse the melted substance with air bubbles and bake it into a block of neoprene foam. Hereafter, they slice this block in any neoprene thickness we need to make your wetsuits. This ranges from 0.4mm to 10mm thickness and everything in between. Moreover, the elongation, flexibility and insulation characteristics of limestone neoprene is the same or better. Above all, this is why limestone neoprene is one of the most flexible and eco-friendly neoprene types out there.

JAPANESE NEOPRENE

You might know Japan for its high-end neoprene production. For instance, for their rubber chips and CR neoprene blocks, ready to use foam sheets and even for their complete wetsuits. Denka is one of the largest Japanese limestone chip manufacturers. They produce limestone rubber chips for most of the world’s neoprene sheet production.

NATURAL RUBBER AND YULEX PURE

A completely different way of making wetsuits is by using natural rubber. Natural rubber is locally known as caoutchouc and it is made from the material harvested from the latex sap of rubber trees. It mainly consists of polymers of the organic compound isoprene and water. Rubber trees grow in tropical areas around the world. Yulex for instance, uses this natural rubber as the main ingredient to make neoprene-like materials, suitable for wetsuit manufacturing. Yulex is a very appealing alternative as long as the rubber tree plantations are FSC certified.

SBR FOAM

SBR foam is similar to neoprene foam and can be lined with nylon or polyester to get the same appearance as a normal neoprene wetsuit. However, SBR foam has poor elongation capabilities and is hardly ozone or chemical resistant. This is why manufacturers mainly use SBR foam in very cheap and poor quality wetsuits. In other words, avoid SBR for your next winter wetsuit.

LINING

LINING

By lining a wetsuit we make it resistant to abrasion, impact, and damage during use. A wetsuit is either single lined or double lined. Examples of single lined neoprene are smoothskin or glideskin. Different manufacturers produce lining from polyester, nylon, spandex or lycra.

DOUBLE LINED NEOPRENE SINGLE LINED NEOPRENE

DOUBLE LINED NEOPRENE SINGLE LINED NEOPRENE

What is double lined neoprene or double nylon neoprene? After we slice neoprene foam into sheets of the right thickness, we laminate both sides with a stretchy fabric layer. By doing this, we make the neoprene more durable. Moreover, by lining the outside of the neoprene, we protect it from fingernails that could cut through the fabric.

SINGLE LINED NEOPRENE

Single lined neoprene goes by a lot of names. For example mesh, glideskin or smoothskin. The finer the mesh, the smoother and shinier the skin. In addition, single lined neoprene has supreme insulation characteristics by protecting you from windchill.

WINDCHILL PROTECTION

WINDCHILL PROTECTION

We use single lined neoprene on the chest and back panels of our wetsuit to keep you warm in windy and cold conditions. Single lined neoprene protects you against windchill and keeps you warmer than double lined neoprene. In addition, we line the inside of our single lined panels with a nylon or polyester knitted lining for comfort to the skin.

INSIDE LINING

INSIDE LINING

Neoprene inside lining is the knitted and laminated finish on the inside of a wetsuit. Lining is made from polyester, nylon, spandex, lycra or a combination of these materials. Inside lining is defined by different characteristics.

THERMAL INSULATION

Thermal insulation is the reduction of heat transfer between objects with different temperatures. In the case of a wetsuit, it refers to the capability of a wetsuit to protect you from the cold water and wind. This results in retaining your body heat inside the wetsuit. Therefore, the thicker the neoprene foam, the better the insulation and the warmer you feel in cold water.

ELONGATION

ELONGATION

Elongation is the percentage of the stretch of neoprene raw foam. We measure the elongation before we laminate the lining onto the foam. The more flexible the foam, the higher the elongation percentage. Less flexible and stiffer foam has about 150-200% elongation. Soft, very flexible and usually lighter foam sits around the 350~400% mark.

OZONE AND UV RESISTANCE

Neoprene foam deteriorates over time, it becomes brittle and it will start cracking. However, the longer this takes, the better the neoprene foam quality. The main factor that determines this is the amount of resistance against Ozone in the atmosphere and UV rays from the sun. In other words, to increase your wetsuit lifespan, never leave your wetsuit to dry in direct sunlight.

PAHS FREE

PAHs are compounds with a potential increased risk of certain diseases. They exist not only in tire products, but also in other common rubber products. Examples of toxic PAHs are Acenaphthene, Acenaphthylene, Anthracene, Fluoranthene, Fluorene, Phenanthrene, Pyrene, Chrysene, and Dibenzo anthracene.

The German Committee for Product Safety, aligned with the REACH Annex XVII PAHs, has determined the requirements for 18 PAHs permissible limits in consumer goods. SRFACE neoprene is categorized as Category 2 (Other products) which most parameters out of 18 must be under 0.5ppm. On other words, don’t worry, no harmful PAHs can be found in SRFACE wetsuits. We only sell products that are REACH SVHC list compliant. Read more about this topic here.

CONCLUSION

CONCLUSION

When you buy a wetsuit, always look for the type of neoprene that matches your needs. However, don’t be fooled by all those fancy names for neoprene. It all comes down do what’s on the inside.

Ready to surf?

Shop from €159