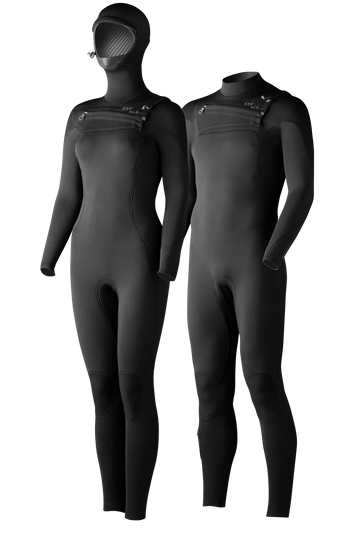

THE ULTIMATE WETSUIT

SRFACE wetsuits put high-end features, a-grade materials, a proven panel layout and an affordable price into one. We keep our wetsuits affordable by applying a direct-to-consumer business model, not by cutting corners on quality, technology or materials. Find out exactly what wetsuit materials and technologies we use to make our high-end wetsuits.

LIMESTONE NEOPRENE

LIMESTONE NEOPRENE

One of the most important SRFACE wetsuit materials is limestone neoprene. Limestone neoprene is used for the SRFACE Heat and Flex Wetsuit. The main neoprene compound for most wetsuits on the market remains chloroprene. But instead of using ‘dirty’ petroleum-based ingredients, SRFACE uses calcium carbonate from limestone to form chloroprene rubber chips. We melt these rubber chips in an oven and they go through a chemical process. After this, we infuse the melted substance with air bubbles and bake it into a block of limestone neoprene foam. We then slice it in any neoprene thickness needed to make your wetsuits, ranging from 0.4mm to 10mm thickness and everything in between. Durability, flexibility and insulation characteristics of limestone neoprene are better than its petroleum-based neoprene predecessor. This makes limestone neoprene one of the most flexible and warm neoprene types out there. Read more about limestone neoprene.

Featured wetsuits

YULEX® NATURAL RUBBER

Our Eco suits are made with Yulex®, this is a neoprene free material. This flexible foam is made from natural rubber which is sustainably harvested from rubber trees in Sri Lanka. The flexible plant-based rubber is purified and made into a high quality closed cell foam, maximizing your performance and enjoyment while doing the minimum harm to our environment. All Yulex rubber plantations are FSC certified.

ECO CARBON BLACK

ECO CARBON BLACK

Neoprene foam as we know it is black. However, rubber chips, the neoprene raw materials are yellow. One of the important ingredients of limestone neoprene is also what colours it black. We call this ingredient eco carbon black and we harvest it by recycling scrap rubber tires. It utilizes a new technology called tire pyrolysis. This significantly reduces energy consumption and CO2 emission during the neoprene production process.

DOPE-DYE

DOPE-DYE

Dope dyed yarns are new energy and water-saving environmentally friendly fabrics. Dope dyeing is a process to colour the outside and inside nylon or polyester lining on wetsuits. Usually, manufacturers knit the fabric first, then dye it into the colour needed afterwards. However, this causes more pollution. We create dope dyed yarns by adding masterbatch colourant to the polymer melt in spinning. We do this before the knitting process to save water, energy and polluted rinsing water (up to 80%). After, we weave the dope dyed yarns into a knit and we laminate it onto both the inside and outside of our neoprene sheets. The colour is deeper and fades less too. Nowadays more and more brands are using dope-dye nylon lining on their high-end wetsuits.

AQUA-α WATER-BASED LAMINATION GLUE

Remember the chemical smell of a new wetsuit? That smell will soon be a thing of the past. Traditional lamination glue for wetsuits is a dirty business. SRFACE exclusively works with a water-based lamination glue called aqua-α on all our wetsuits. This saves up to 600 grams of solvents per wetsuit. Don’t worry, aqua-α, although water-based, won’t dissolve in water.

REACH COMPLIANT / PAHS FREE

PAHs, or Polycyclic Aromatic Hydrocarbons, are a class of chemicals that occur naturally in coal, crude oil, and gasoline. PAHs generated from these sources can bind to or form small particles in the air and can form a potential health risk. All SRFACE wetsuits are PAHs free and 100% REACH compliant. You can find more information on REACH guidelines here.

360° STRETCH WETSUIT LINING

360° STRETCH WETSUIT LINING

360° stretch wetsuit lining is a variety of super or hyper stretch nylon combined with spandex lining. We laminate both the inside and outside of our wetsuits with a stretchy jersey. 360° stretch lining is the high-end version of this material and stretches in all directions. It makes for a flexible, soft to the skin, comfortable wetsuit which is easier to put on and take off.

SMOOTHSKIN CHEST AND BACK PANEL

SMOOTHSKIN CHEST AND BACK PANEL

The smoothskin chest and back panel of a wetsuit plays an important role in the fit of the wetsuit. Nowadays, you’ll see a lot of wetsuits with a combined chest and front leg panel made with double lined neoprene. Although it might look cool, the fit and insulation qualities drop drastically. This is why SRFACE wetsuits feature a smoothskin chest and back panel. Combined with a plush insulation quick-dry inside lining for added comfort and warmth.

SMOOTHSKIN

SMOOTHSKIN

Smoothskin is a type of single lined neoprene. It is similar to glideskin, but more sticky. This helps to stick to the wax of your surfboard when paddling. To protect against windchill, we use smoothskin on our chest and pack panels. This means your sessions will last longer with insulation where you need it most. Smoothskin is flexible but is more fragile than double lined neoprene. So be careful not to damage your wetsuit with your fingernails.

ABRASION-RESISTANT KNEE PADS

ABRASION-RESISTANT KNEE PADS

Wetsuit knee pads protect your knees when duck diving. Therefore, we use extra strong material for our knee pads. They also protect the wetsuit in this area from wearing out. Kneepad outside lining is abrasion-resistant. On top of that, the neoprene foam inside the knee pad has a high impact and compression rate to protect your knees from impact. The inside of the knee panel is lined with 360° stretch lining for flexibility and comfort.

MELCO DOTS

Melco dots are a great way to add an extra layer of protection to your wetsuit. Melco dots are a Japanese reinforcement material that is heat welded on the inside of a wetsuit. Thereby reinforcing certain stress areas to make our wetsuit last longer. Melco dots prevent overstretching, which can lead to tearing the wetsuit. Melco material can be used as heat welded tape or heat welded patches or dots. You can find these patches on the inside of our wetsuits, where multiple seams meet in one place.

YKK ZIP

YKK ZIP

Maybe the most important of SRFACE wetsuit materials, the zip. YKK zips are the standard in zip technology. This market-leading company makes high-quality wetsuit zips. In addition, they don’t corrode in seawater. These zips last really long and can take some abuse, such as ripping off your wetsuit after a long surf.

Ready to surf?

Shop from €159