WHAT IS LIMESTONE NEOPRENE?

It might sound unusual, but many high-end wetsuits today are made using limestone-based neoprene. What is limestone neoprene, and how is this done? The world is full of surprises: We can turn a rock into a wetsuit. But it’s not a simple process.

OLDSCHOOL NEOPRENE

Let’s rewind to the 1930s, when DuPont invents synthetic foamed rubber and calls it neoprene. At that time, wetsuits didn’t exist yet. Different parties developed the first wetsuits for army divers, so they could stay in cold water longer. Neoprene is an elastomer with the chemical name polychloroprene. A chemical process binds strings of a clear liquid called chloroprene together. The original chloroprene wetsuits were made using petroleum-based chemicals, which have a higher environmental impact. Consequently, different companies reinvented neoprene over the years to become more sustainable.

LIMESTONE NEOPRENE WETSUITS

LIMESTONE NEOPRENE WETSUITS

What is limestone neoprene and how is it different from petroleum-based CR chloroprene? In the 1960s, a new way of making neoprene evolves. The main neoprene compound remains chloroprene. However, instead of petroleum-based feedstocks, calcium carbonate from limestone is used as a raw material. This ingredient forms chloroprene rubber chips. These are melted down in an oven and go through a chemical process. The melted substance is infused with air bubbles and baked into a block of neoprene foam. The manufacturer then slices this block into neoprene sheets. At this stage, we determine the neoprene thickness. It can vary between 0.5mm, all the way up to 7mm when used for surfing wetsuits.

Choose your wetsuit

LIMESTONE NEOPRENE CHARACTERISTICS

LIMESTONE NEOPRENE CHARACTERISTICS

We determine the quality of neoprene by a couple of factors. Firstly, the elongation percentage. This measures the amount of flexibility in the neoprene. The higher the number, the more stretchy the neoprene is, which is generally preferred for flexibility and comfort. Secondly, we measure the softness and weight by calculating the density. The heavier the foam, the harder, thus affecting the stretch. We consider softer and lighter foam to be more high-end. Thirdly the ozone and UV resistance. High resistance to ozone and UV rays results in more durable neoprene. This also means it is less easy to crack or get brittle. Depending on the foam formulation, these characteristics of limestone neoprene can be more advanced than traditional petroleum-based neoprene. This makes limestone neoprene, when used in the right grade, one of the most flexible and warm neoprene types available. Limestone neoprene is not considered a sustainable material, but it currently offers strong performance characteristics compared to other foam types.

NEOPRENE AND ITS SUSTAINABLE ALTERNATIVES

There are different types of neoprene used in wetsuits today. The introduction of limestone-based neoprene made a big impact on wetsuit manufacturing and is now widely used in high-end wetsuits. Some companies use different names for their limestone-based alternatives. You might have heard of Japanese Yamamoto neoprene, which is used in some high-end wetsuit models. Other versions of limestone neoprene are Bioprene and Geoprene wetsuits. Not long ago, we worked exclusively with limestone neoprene. The elongation, flexibility, and insulation characteristics of limestone neoprene can be very good compared to traditional petroleum-based neoprene, depending on the specific foam formulation. This makes limestone neoprene a popular choice for flexible and warm wetsuits.

In recent years, plant-based natural rubber foams have emerged as an alternative to traditional neoprene. Yulex was one of the first materials to bring this concept to the wetsuit market, developed in collaboration with Patagonia. Today, several natural rubber foams exist and continue to improve.

Natural rubber foams are considered among the lower-impact material options currently available for wetsuit production. They are typically double-lined, which allows for strong and durable seams between panels, helping to keep water out and retain warmth. While these materials are generally more expensive than limestone neoprene, their performance has improved significantly over the last few years and continues to evolve. In many properties, they already perform very well compared to traditional neoprene.

At SRFACE, we work with material partners to test and develop natural rubber foams. These materials are intended for use in our Eco wetsuit range and future products.

DOUBLE LINED NEOPRENE

DOUBLE LINED NEOPRENE

After slicing limestone neoprene foam into sheets of the right thickness, we laminate it with a stretchy fabric layer. To make it more durable, lining can be applied on both sides of the wetsuit. On top of that, it protects it against outside influences like UV and ozone. The outside lining also offers protection from fingernails cutting through the neoprene. We line the inside of our wetsuits with flexible and soft material. Therefore, your wetsuit feels comfortable to wear on the skin. The main body panels of most high-end wetsuits, including ours, are lined with a quickdry plush lining. Resulting in an insulating layer between the body and the cold water. This quickdry plush fabric helps the material to dry faster too, so you can be ready for your next session in no-time. Double lined neoprene is neoprene which has fabric lining laminated onto both sides of the neoprene foam.

SINGLE LINED NEOPRENE

SINGLE LINED NEOPRENE

With a metal embossing tool we melt a raw neoprene foam sheet’s surface. This creates a ‘skin-like’ coating to the foam. Single lined neoprene is also known as mesh, smoothskin or glideskin. Single lined neoprene panels are mainly used on the outside of chest and back panels. Specifically on cold water surfing wetsuits. High-end winter wetsuits often use a single-lined neoprene chest and back panel such as smoothskin. The smooth outside doesn’t absorb water and helps the water run down the surface immediately. Thereby protecting your body from windchill, so you can stay in the water longer. Wetsuits that are completely made out of single lined neoprene do exist but are not commonly used for surfing. However, you might find full single lined wetsuits to be used for open water swimming or triathlon.

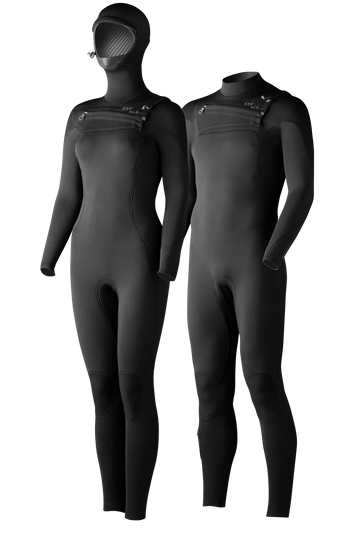

Featured wetsuits

SRFACE WETSUITS

Over the past few years, limestone neoprene became the standard for most high-end wetsuits. However, this doesn’t mean oldschool petroleum neoprene is a thing of the past. Some brands still use it in mid and entry-level wetsuits. Many high-end wetsuits today use limestone-based neoprene because of its flexibility, warmth and durability characteristics. We make our wetsuits with the highest grade materials and technologies available. This includes the most flexible limestone neoprene foam. The double lined wetsuit panels feature the most flexible (360° limitless stretch) outside lining available. SRFACE uses single lined smoothskin neoprene chest and back panels to avoid windchill. We line the body panels with a comfortable and heat-retaining quick-dry plush insulating inside lining. Finally, we finish our glued and blind stitch seams with heat-welded neoprene tape on the inside and liquid rubber-seals on the outside.

Read more about SRFACE wetsuit materials.

Ready to surf?

Shop from €159