ECO-FRIENDLY WETSUITS: ALL YOU NEED TO KNOW

There are a lot of self proclaimed eco-friendly wetsuits out there, but they’re not all that ‘green’. Luckily, wetsuit technology is developing rapidly and the biggest manufacturers are taking environmental concerns seriously. The processes and technologies available are becoming more eco-friendly by the day. It’s only a matter of time before most of the big wetsuit brands adopt these more sustainable wetsuit technologies. Below we will cover the main eco-friendly wetsuit developments implemented over the past couple of years.

ECO-FRIENDLY NEOPRENE

As wetsuit brands become more aware of their impact on the environment, limestone neoprene rapidly gains popularity. Different companies use different names for their more environmentally friendly neoprene. Some brands use Japanese Yamamoto neoprene or Geoprene in their high-end wetsuit models. Bioprene is a different version of limestone neoprene, made from seashells. And finally, Yulex uses natural rubber as main ingredient.

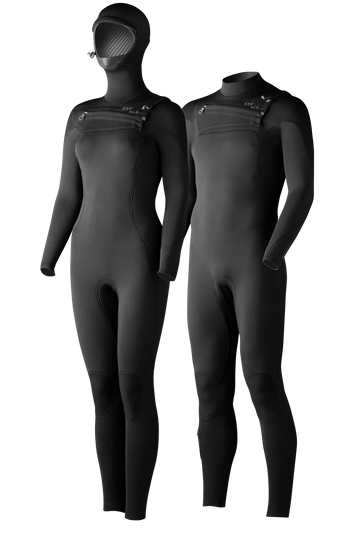

Featured wetsuits

LIMESTONE NEOPRENE

CR neoprene, or traditional neoprene, was invented in the 1950s. Many wetsuit manufacturers still use it today, even though it is harmful to the environment. In the 1960s, an alternative method for making neoprene was developed. Instead of using petroleum, technological advancements open up the possibility to use calcium carbonate from limestone to make neoprene. Japan is home to most of limestone mines, where the material is processed to form rubber chips. These are melted into a rubber foam, filled with air bubbles, giving limestone neoprene its good thermal insulating characteristics. The elongation, flexibility and insulating characteristics of limestone neoprene are better than its petroleum-based predecessor.

NATURAL RUBBER AND YULEX NEOPRENE-FREE NATURAL RUBBER

Natural rubber is used as an alternative material to produce eco-friendly wetsuits. Naturalprene and neoprene free Yulex are types of neoprene that use natural rubber as their main ingredient. SRFACE Eco wetsuits are made with Yulex®, a neoprene free material. This flexible foam is made from natural rubber which is sustainably harvested from rubber trees in Sri Lanka.

RECYCLING WETSUITS

To reduce waste material when making wetsuits, it’s important that a wetsuit designer develops a material efficient panel layout. This results in wetsuit patterns with a low material yield rate. This means better cutting efficiency when cutting single panels out of a neoprene sheet. The biggest wetsuit manufacturers recycles their neoprene offcut waste to make qualified products. However, there are still lots of smaller wetsuit factories that don’t care much about the environment and throw offcuts into landfill.

AQUA-Ɑ WATER-BASED LAMINATION GLUE

Water-based glue is slowly taking over the wetsuit industry. Remember the chemical smell of a new wetsuit? That will soon be a thing of the past. We now exclusively use a water-based lamination glue called aqua-ɑ. We use aqua-ɑ to laminate lining onto neoprene sheets before these are cut and stitched into wetsuits. This saves up to 600 grams of harmful solvents per wetsuit. Although aqua-ɑ glue is water-based, it won’t dissolve in water. It is as strong as, if not stronger than traditional wetsuit glue. Aqua-ɑ is yet another step towards making eco-friendly wetsuits.

ECO CARBON BLACK WETSUITS

Neoprene raw material is yellow, however, nearly all neoprene foam you encounter in wetsuits is black. One of the important ingredients of limestone neoprene is what colours it black. We harvest this ingredient through recycling scrap rubber tires by utilizing a new technology called tire pyrolysis. This significantly reduces energy consumption and CO2 emissions during the neoprene production process. We call this colouring technique eco carbon black.

WHAT IS DOPE DYE?

Dope dye is a new environmentally friendly fabric dyeing technology that saves energy and water. We use this process to colour the outside and inside nylon or polyester lining on our wetsuits. We create dope dyed yarns by adding masterbatch colourant to the polymer melt in spinning before the knitting process. This saves water, energy and polluted rinsing water (up to 80%). We weave the dope dyed yarns into a knit and laminate it onto both the inside and outside of the sliced neoprene sheets. The colour is deeper and fades less too.

RECYCLED LINING

The lining laminated onto the neoprene panels, on both inside and out, can now be made with recycled yarns made from PET bottles. This reduces plastic waste pollution that could have ended up in the ocean. We expect the technology to evolve rapidly and to create recycled materials that are just as good as the non-recycled ones.

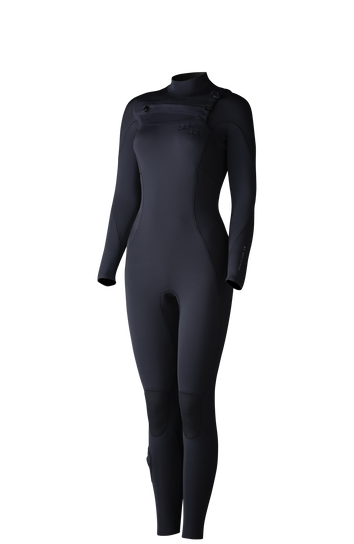

Choose your wetsuit

SOLAR ENERGY

Solar energy is making its entry in the biggest wetsuit manufacturing plants, reducing CO2 emissions drastically. Our goal is to make our wetsuit factories rely solely on their own power source in the near future.

REACH COMPLIANT / PAHS FREE

Most synthetic rubber products such as neoprene contain harmful PAHs (Polycyclic Aromatic Hydrocarbons). These are a class of chemicals that occur naturally in coal, crude oil and gasoline. PAHs can cause a potential health risk as particles generated from these sources can bind to or form small particles in the air. Strict regulations in Europe make sure that high-end wetsuits sold in Europe are PAHs free and 100% REACH compliant. Find more information on REACH guidelines here.

FAIR TRADE WETSUITS

It is now possible to produce eco-friendly wetsuits with a Fairtrade classification. Our wetsuit manufacturing plants is now fairtrade certified and can produce fairtrade goods. It’s down to individual brands to get the certification themselves, as their entire program needs to be fairtrade certified.

ECO-FRIENDLY BUSINESS MODEL

The eco-friendly wetsuit cycle doesn’t end at the factory. Other aspects of the industry are changing for the better. Think of carbon neutral shipping and packaging made from recycled materials. In addition, direct-to-consumer wetsuit brands have the benefit of less shipping miles per wetsuit. Working without shops and distributors means we ship our wetsuits directly to the consumer. And don’t forget what you can do to avoid pollution: Recycle or donate your old wetsuit.

RECYCLE A WETSUIT

There comes a time when your wetsuit just doesn’t do its job anymore. A wetsuit will eventually stretch out, the neoprene will become brittle, the lining may start to delaminate or holes might appear in the seams or panels. This is when you know it’s time for a new wetsuit. Even though you can’t surf in it anymore, it would be a waste to throw your wetsuit in the bin and there are multiple ways that you can recycle your old wetsuit. There are companies that up-cycle wetsuits into yoga mats, or use it as filling for a boxing punch bag. If your wetsuit is still in a usable condition, donate it to charity or a surf program that helps people in need. In conclusion, take care of your wetsuit and recycle it!

Ready to surf?

Shop from €159